Handheld Galvanized Steel Laser Welding Machine

Theo MA1 Laser Welding Machines

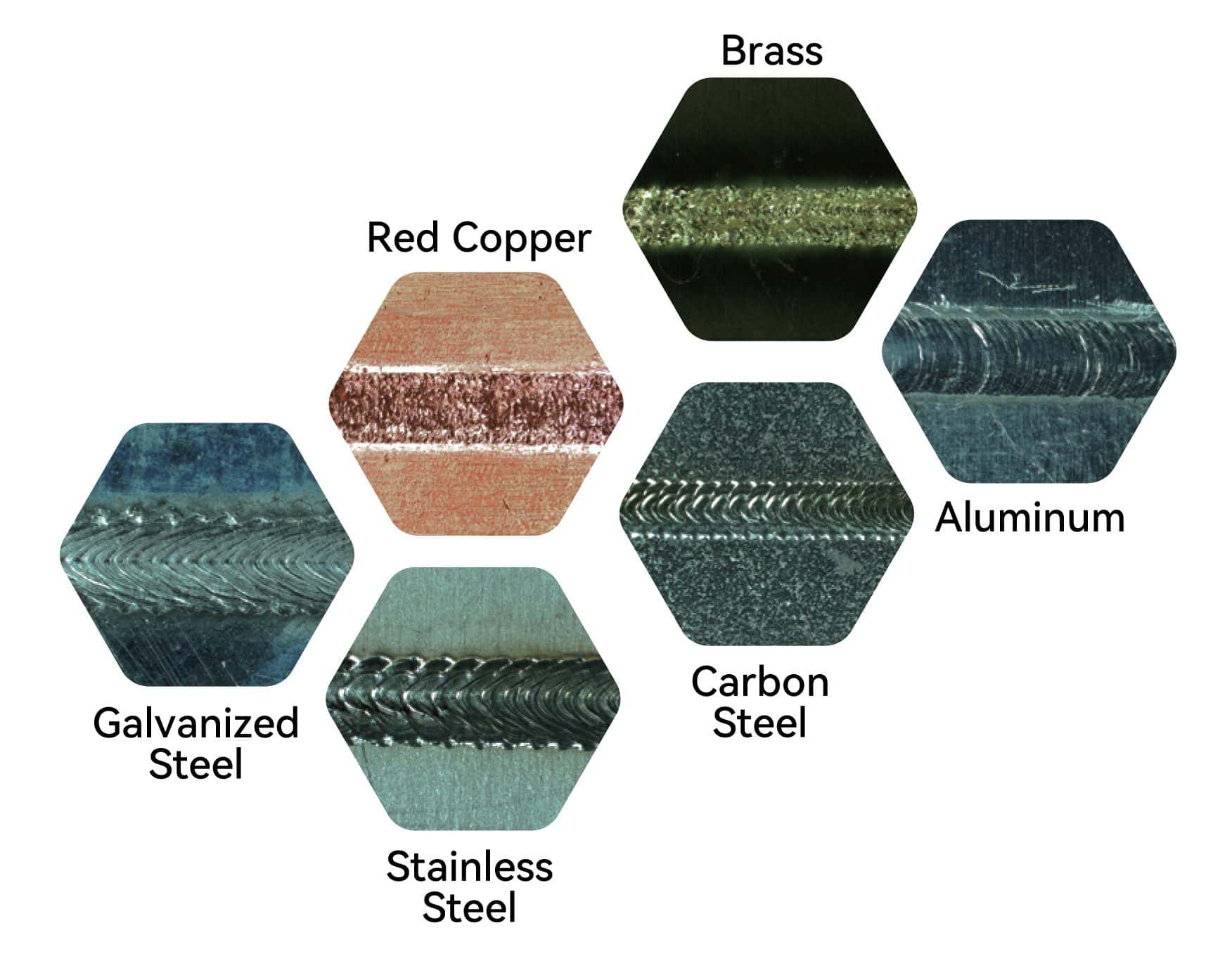

The MA1 series are the perfect cutting edge solution as a portable galvanized steel laser welder. The MA1 offers versatile material compatibility up to 6.5mm / 1.4″. With compatibility for a wide range of materials, including stainless steel, galvanized steel, mild steel, aluminum, nickel alloys, titanium, and copper, up to a thickness of 6.5mm, this tool ensures efficient and high-quality welding every time.

The MA1 series minimizes part distortion due to its low heat input, preserving the integrity of your materials. Moreover, the strong and beautiful welding seams produced by this series require no further cleaning, saving you valuable time and enhancing the final appearance of your products.

Portable Design

Up to 4x Faster than Arc Welding

Easy to Learn, Easy to Operate

80% less energy consumption

Certified Safety and Quality

Easy to Learn, Effortless Control

With its innovative features and intuitive design, the Theo MA1 is remarkably easy to learn and operate. The 7" LED touch screen and intelligent operating system make the MA1 a breeze to use, supporting multiple languages for seamless communication. Whether you're a seasoned professional or a beginner, say goodbye to costly training programs and hello to immediate productivity. The MA1 empowers welders of all levels to create high-quality and consistent welds, saving you time and money.

The Industry’s Lightest Welding Torch

Weighing in at an astonishingly light 680g (1.5 pounds), this torch is specifically designed with your comfort in mind, allowing for extended use without the burden of fatigue. With its impressive built-in wobble function, controlled by an advanced laser system, the MA1 enables weld widths of up to 4.0mm (0.16"), resulting in flawless weld seams of the highest quality.

For added operational safety, the torch is equipped with a double-secured contact sensor, ensuring that operation is only possible when the trigger is in hand contact and in contact with the workpiece. And that's not all – the Theo MA1 series also comes with a wire feeder module to cater to your deeper welding needs, supporting wire diameters ranging from 1.0mm to 0.8mm. Whether you're working with carbon steel, stainless steel, aluminum, or other alloys, this torch is the perfect choice for all your welding requirements.

Versatile Material Compatibility up to 6.5mm / 1/4"

The MA1 series are versatile tools designed for high-speed welding. With compatibility for a wide range of materials, including stainless steel, galvanized steel, mild steel, aluminum, nickel alloys, titanium, and copper, up to a thickness of 6.5mm, this tool ensures efficient and high-quality welding every time. The MA1 series minimizes part distortion due to its low heat input, preserving the integrity of your materials. Moreover, the strong and beautiful welding seams produced by this series require no further cleaning, saving you valuable time and enhancing the final appearance of your products.

Boost Profitability with Energy-Efficient Welding

Experience incredible energy savings of up to 80% with the cutting-edge MA1 Series. Unlike other welding technologies, this single-mode technology increases energy density, allowing for high-speed welding without excessive power consumption. This impressive energy efficiency not only ensures superior performance but also translates into significant cost savings. Enhance both your operational efficiency and bottom line with the smart choice of the Theo MA1.

Laser Welding with the Theo MA1 Series vs Traditional Welding

| Traditional welding methods | Handheld laser welding | |

|---|---|---|

| Welding Speed | Average | Up to 4 times faster than TIG |

| Welding Quality | Highly dependent on user experience Welding seams can be rough, irregular and require rework and polishing | Consistent high-quality results. Beautiful and neat welding seams, deep molten pool, and high strength. No cleaning necessary. |

| Training & Learning Curve | Difficult to learn | Easy – Train in less than one hour. Proficiency in 1-2 weeks. |

| Heat affected zone | Large | Small |

| Material Distortion & Deformation | High | Very Low |

| Welding Seam Damage | Potential for Porosity, lack of consistency | Uniform melt pool and great consistency |

| Energy Consumption | High | Low up to 80% reduction in electricity costs |

| Consumables | High welding wire consumption | Precise wire consumptions supported by wired feeding system. |

Atlantic Laser Solutions is your Expert Solution Partner and reseller of the Theo MA1 Series Handheld Laser Welding Machines.

Contact Us

Ready to explore the full potential of the future of handheld laser welding systems? Contact us for a quote, or to learn more about the cutting edge Theo MA1 Series. We’re ready to provide you with expert guidance and answer any questions you might have.