10% off MA1-35, MA1-45, and MA1-65 through September!

Contact us for a free quote today!

Handheld Laser Features

Stable Performance and Reliable Quality

Theo’s MA1 series handheld laser welder is engineered with world-class laser technology, ensuring precise laser control and stable beam quality. Each unit undergoes rigorous testing before leaving the factory, including a 500-hour high- and low-temperature (-10°C–45°C or -14°F–113°F) cycling power test and a 12-hour continuous welding test with 99% power stability. With a laser power source lifespan of approximately 100,000 hours, all our products meet SGS industry standards to guarantee stable and durable beam output.

Compact Handheld Welding Torch

Equipped with a revolutionary laser optic design, our welding torch is impressively lightweight at just 680g (1.5 pounds). Its optical design and QCS output head are seamlessly integrated, providing high transmission efficiency and heat output. Ergonomically crafted for user comfort, the torch is easy to operate.

We’ve also included a built-in wobble function with a multi-point interlock system, allowing operators to work safely all day while consistently delivering high-quality welds.

Compact and Mobile

Theo’s new generation of handheld laser welders is engineered for portability, making it ideal for mobile welding projects.

With options ranging from 28kg to 39kg (62-86 pounds), you can choose the product that best suits your welding needs and performance criteria. The compact design, occupying less than 0.1m3 (3.5 cubic feet), enhances its portability, allowing for easy transport and setup.

Simple and Intuitive

The MA1 series features a 7” LED touchscreen and an intuitive, multi-language operating system. With simple operation modes, it’s easy to get to work. Beginners can consistently deposit good welds with just 1-2 hours of training, significantly reducing both training and production costs.

The device comes pre-loaded with 32 sets of process parameters while also allowing for precise user customization. This feature enables operators to swiftly select welding parameters based on various materials and thicknesses.

Six Robust Safety Measures for Unmatched Protection

The MA1 Series Handheld Welder is a Class IV laser product. To guarantee safe operation, appropriate PPE (Personal Protective Equipment) is essential. At a minimum, laser-safe eyewear should always be worn. Theo includes a pair of goggles with every laser for added safety.

- Laser control switch

- Welding torch trigger switch, torch button

- Gas pressure detection, control switch and security alarm

- Warning lamp

- Safety key switch

- Emergency stop button, laser power switch

- LOOP safety interlock

Portable Design

Up to 4x Faster than Arc Welding

Easy to Learn, Easy to Operate

80% less energy consumption

Certified Safety and Quality

Easy Integration and Operation

All you need is a standard 220 Vac power plug, a connection to industrial shielding gas like argon or nitrogen, and the interlock connection attached to your workpiece to start welding.

The 7-inch LED touchscreen features an intuitive, multi-language operating system. Here, you can easily select from preset welding parameters or input your own precise user-defined settings.

Lightweight, Portable, and Engineered for High Performance

Compared to traditional welding methods, Theo’s MA1 handheld laser welding products significantly boost welding speed (up to four times faster for steels). With this innovative system, individuals of all skill levels can quickly achieve consistent, high-quality welding results across a wide range of materials and thicknesses. They are easy to operate, comply with industry safety standards, save energy, and are eco-friendly.

Portable Laser Uses

The air-cooled fiberlaser system eliminates the need for an external chiller, making welding easier and more efficient than ever before. The MA1 series features stable beam quality, and a laser power range of 800 to 1500 watts. Even novices can be trained to consistently achieve weld depths from 1.5mm to 6.5mm (roughly .25”) with little to no welding wire consumption, ensuring high-quality, strong welds.

The Theo MA1 Series is a compact, user-friendly, and highly efficient high-precision laser welding system that significantly boosts welding speed, reduces training time, and delivers remarkable return on investment compared to traditional methods.

Laser Welding vs MIG and TIG

Hard-to-find skill set, technically complex welding processes, uncomfortable work conditions, low efficiency, unsuitability for special metals and thin sheets, high welding wire consumption, and pre-cleaning and joint preparation required for full penetration. For TIG, vertical welding is notably challenging due to limited direction and operating angles.

Large heat-affected zone: Traditional welding often distorts and discolors the workpiece due to heat, affecting weld quality by introducing porosity, reducing joint strength, and altering grain structure—necessitating further post-processing. Welding materials like copper and aluminum also introduce thickness limitations.

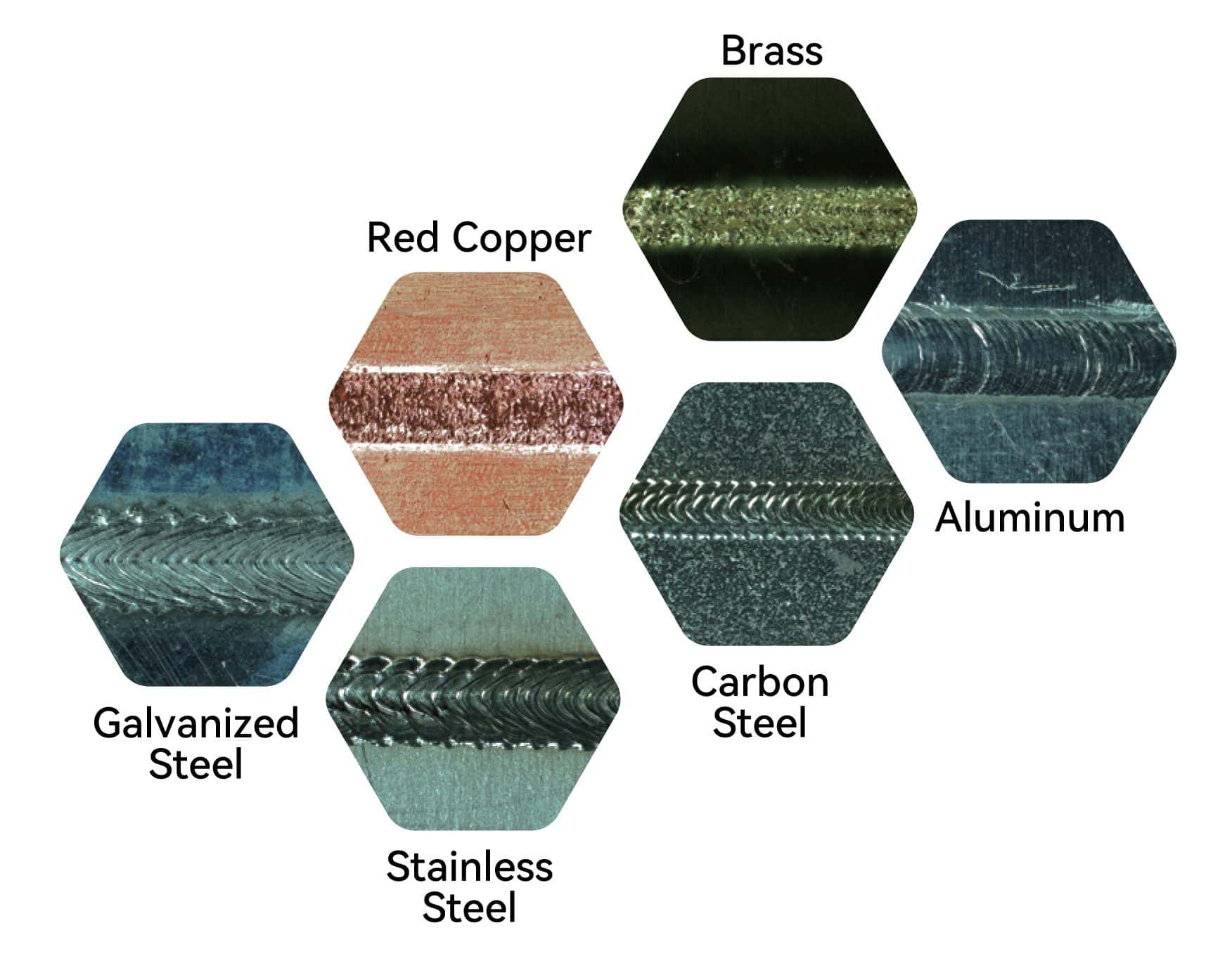

Wire Feeder Unit Included – Integrated Wobble Welding

The units include a wire feeder module for situations where deeper weld penetration is necessary, such as filling gaps or achieving smooth, flush weld profiles. The module supports welding wire diameters of 1.0mm (approximately 1/25”), 1.2mm (approximately 3/64”), and 1.6mm (approximately 1/16”). It is compatible with a variety of materials including:

- Carbon Steel

- Stainless Steel

- Galvanized Steel

- Aluminum

- Copper

- Non-Ferrous Metals

- and Other Alloys.

Laser Welding with the Theo MA1 Series vs Traditional Welding

| Traditional welding methods | Handheld laser welding | |

|---|---|---|

| Welding Speed | Average | Up to 4 times faster than TIG |

| Welding Quality | Highly dependent on user experience Welding seams can be rough, irregular and require rework and polishing | Consistent high-quality results. Beautiful and neat welding seams, deep molten pool, and high strength. No cleaning necessary. |

| Training & Learning Curve | Difficult to learn | Easy – Train in less than one hour. Proficiency in 1-2 weeks. |

| Heat affected zone | Large | Small |

| Material Distortion & Deformation | High | Very Low |

| Welding Seam Damage | Potential for Porosity, lack of consistency | Uniform melt pool and great consistency |

| Energy Consumption | High | Low up to 80% reduction in electricity costs |

| Consumables | High welding wire consumption | Precise wire consumptions supported by wired feeding system. |

Atlantic Laser Solutions is your Expert Solution Partner and reseller of the Theo MA1 Series Handheld Laser Welding Machines.

Contact Us

Ready to explore the full potential of the future of handheld laser welding systems? Contact us for a quote, or to learn more about the cutting edge Theo MA1 Series. We’re ready to provide you with expert guidance and answer any questions you might have.